GET H2 Nukleus and expansion

The GET H2 partners bp, Evonik, Nowega, OGE, Thyssengas and RWE want to jointly establish one of the first integrated hydrogen projects with a publicly accessible hydrogen infrastructure. The GET H2 projects create the core for a German and European hydrogen economy. Along the entire value chain, the participating companies are continuously developing a high-performance infrastructure, thus enabling connections for all sectors and links to other hydrogen networks. A large part of the building blocks are nominated for funding as IPCEI (Important Project of Common European Interest).

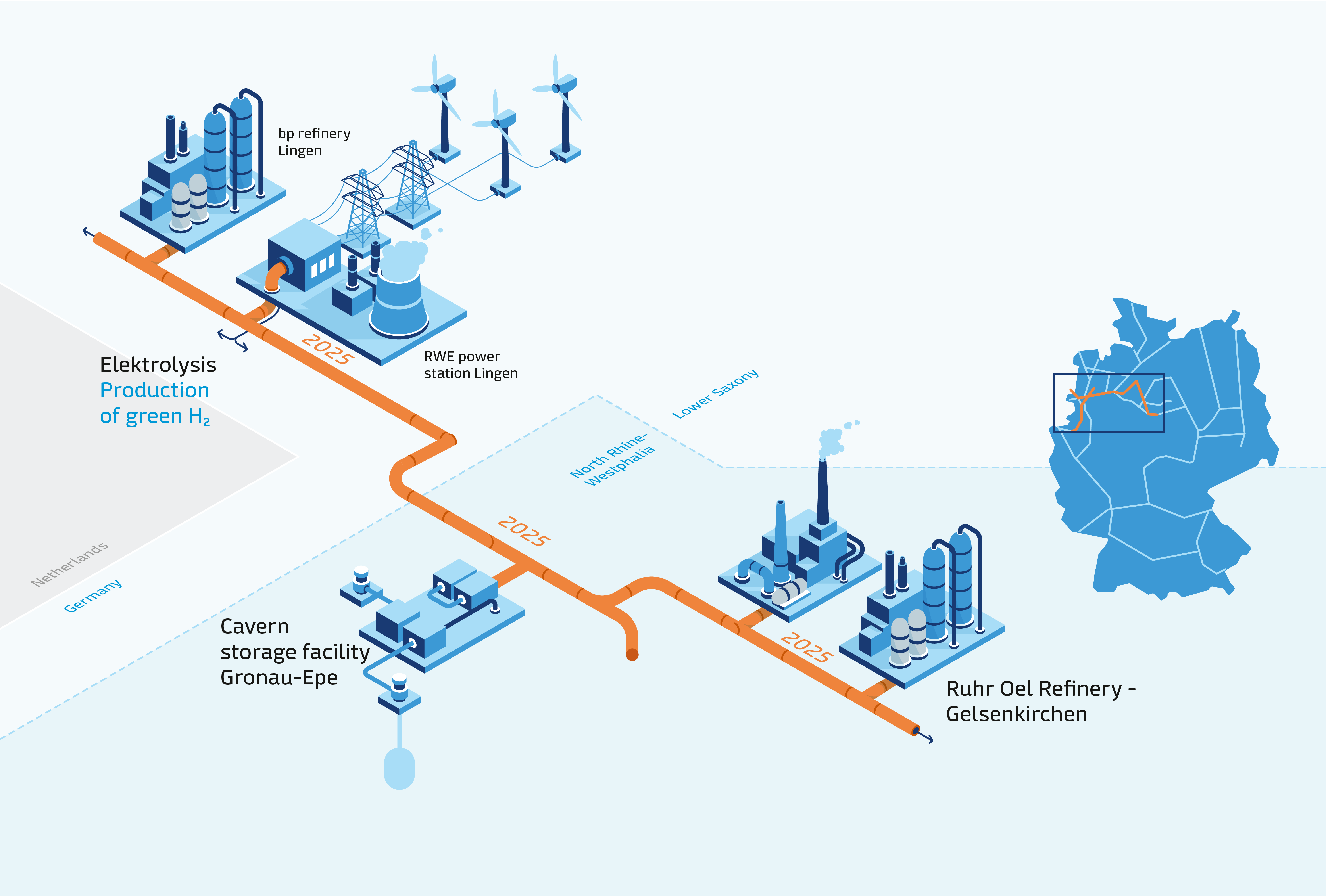

2025: GET H2 Nukleus

By 2025, the GET H2 partners bp, Evonik, Nowega, OGE and RWE want to jointly connect the production of green hydrogen with industrial consumers in Lower Saxony and NRW. The approximately 130-kilometre pipeline network from Lingen to Gelsenkirchen is to become the first H2 network in the regulated sector with non-discriminatory access and transparent prices.

By 2025, the GET H2 partners bp, Evonik, Nowega, OGE and RWE want to jointly connect the production of green hydrogen with industrial consumers in Lower Saxony and NRW. The approximately 130-kilometre pipeline network from Lingen to Gelsenkirchen is to become the first H2 network in the regulated sector with non-discriminatory access and transparent prices.

- The green hydrogen is to be generated from wind power in Lingen, Lower Saxony. To this end, an electrolysis plant with a capacity of 300 MW (100 MW operational by 2025) is to be built at the site of the RWE power plant in Lingen.

- Existing gas pipelines of the transmission system operators Nowega and OGE will be converted to transport 100 percent hydrogen.

- Nowega is building a new pipeline to connect the electrolysis with the main pipeline leading towards the Ruhr area, and Evonik is also constructing a partial new pipeline between the Marl Chemical Park and bp’s Ruhr Oel refinery Gelsenkirchen.

- The climate-neutral raw material will be transported to industrial customers via this infrastructure.

- The companies use the green hydrogen in their production processes and thus significantly reduce their CO2 emissions.

- Nowega and OGE are connecting the gas storage facilities of RWE Gas Storage West in Gronau-Epe via another new pipeline. A new cavern storage facility for hydrogen will be built there.

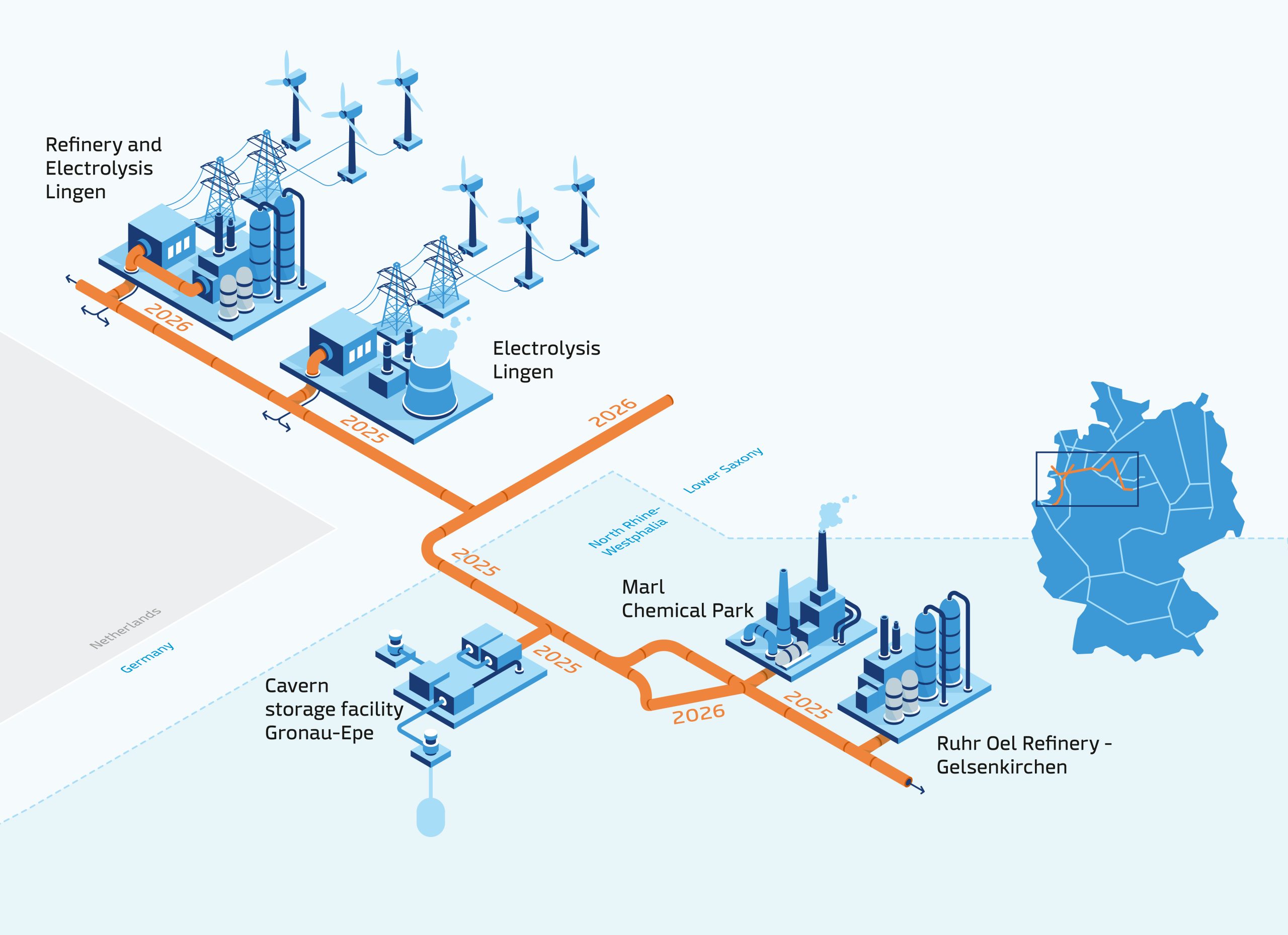

2026: Expansion of the infrastructure

In Lingen a second 100 MW electrolysis plant with a connection to the hydrogen network is being built by bp in the Lingen Green Hydrogen project. Among other things, the plant will supply the adjacent refinery with green hydrogen. By building a new connecting pipeline between Dorsten and Marl, OGE and Nowega are creating a further connection for Evonik’s chemical park in Marl. Nowega is also converting another pipeline section to transport hydrogen, which will be used to connect the Salzgitter AG steelworks in the future. The hydrogen storage facility of RWE Gas Storage West in Gronau-Epe goes into operation. The storage of hydrogen is a crucial building block for ensuring security of supply and storing renewable energies in the long term. The RWE electrolysis in Lingen is expanded to 200 MW.

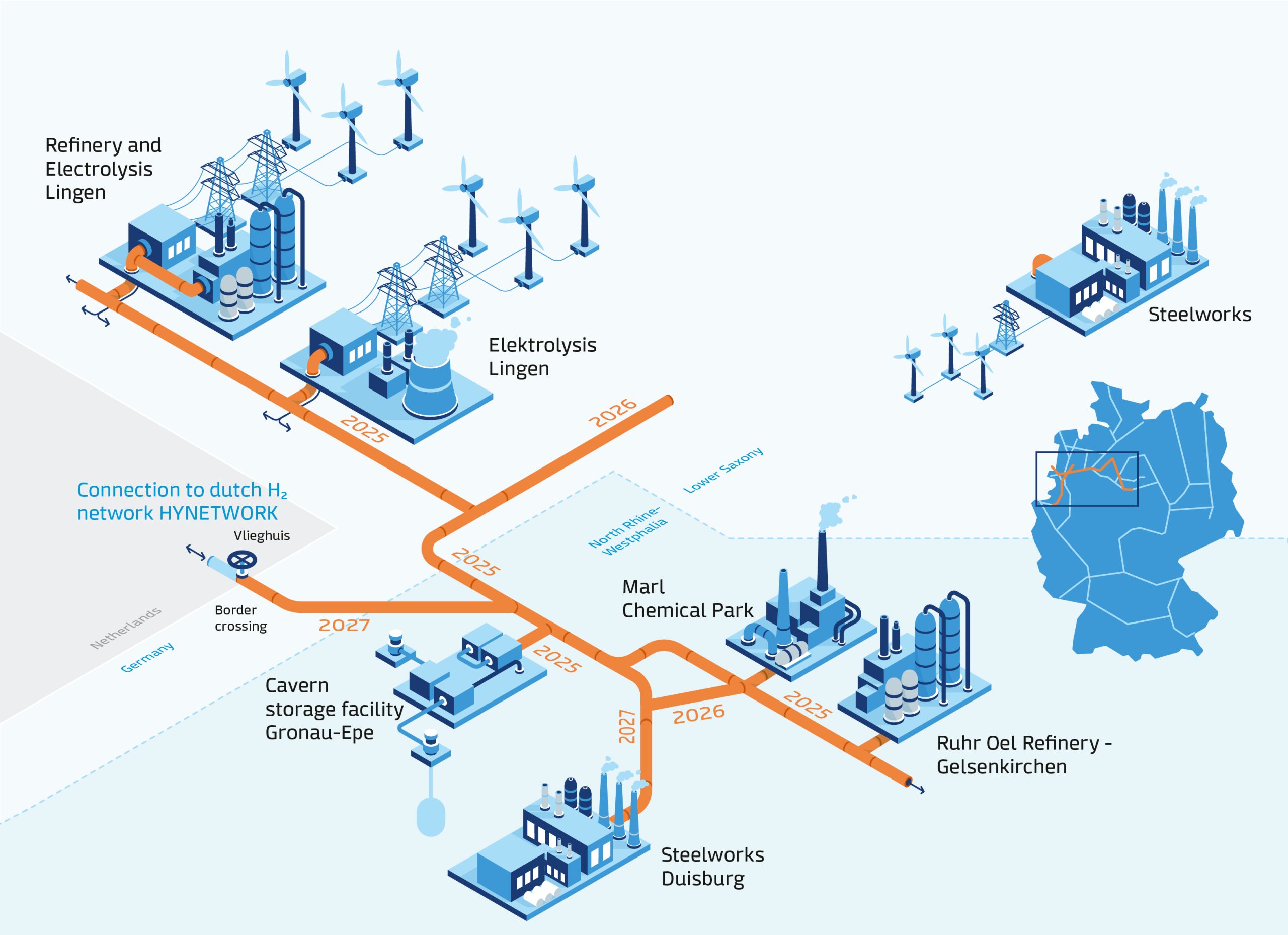

2027: Connection to the Netherlands and launch in Salzgitter

Further important steps to expand the infrastructure and increase the performance will be implemented by 2027:

- The network is expanded to the Dutch border. The connection to the import point Vlieghuis will be implemented by GET H2 partner Thyssengas. The transmission system operator is converting existing gas pipelines between Kalle, Ochtrup and Vlieghuis to transport 100% hydrogen. This step will create the connection to the Dutch hydrogen network HYNETWORK. This pipeline network connects Germany, the Netherlands, Belgium and France and connects the port of Rotterdam as an important import point.

- Salzgitter AG is commissioning an electrolyser at its steelworks, which is supplied with electricity from wind energy. This is part of the SALCOS project, Salzgitter AG’s climate initiative to make steel production climate-friendly.

- By building the new pipeline from Dorsten to Hamborn, OGE and Thyssengas are creating an additional connection in the direction of the Ruhr area to connect the ThyssenKrupp steelworks, which is also converting its production to hydrogen-fuelled direct reduction plants.

- The RWE electrolysis plant in Lingen is further expanded to 300 MW.

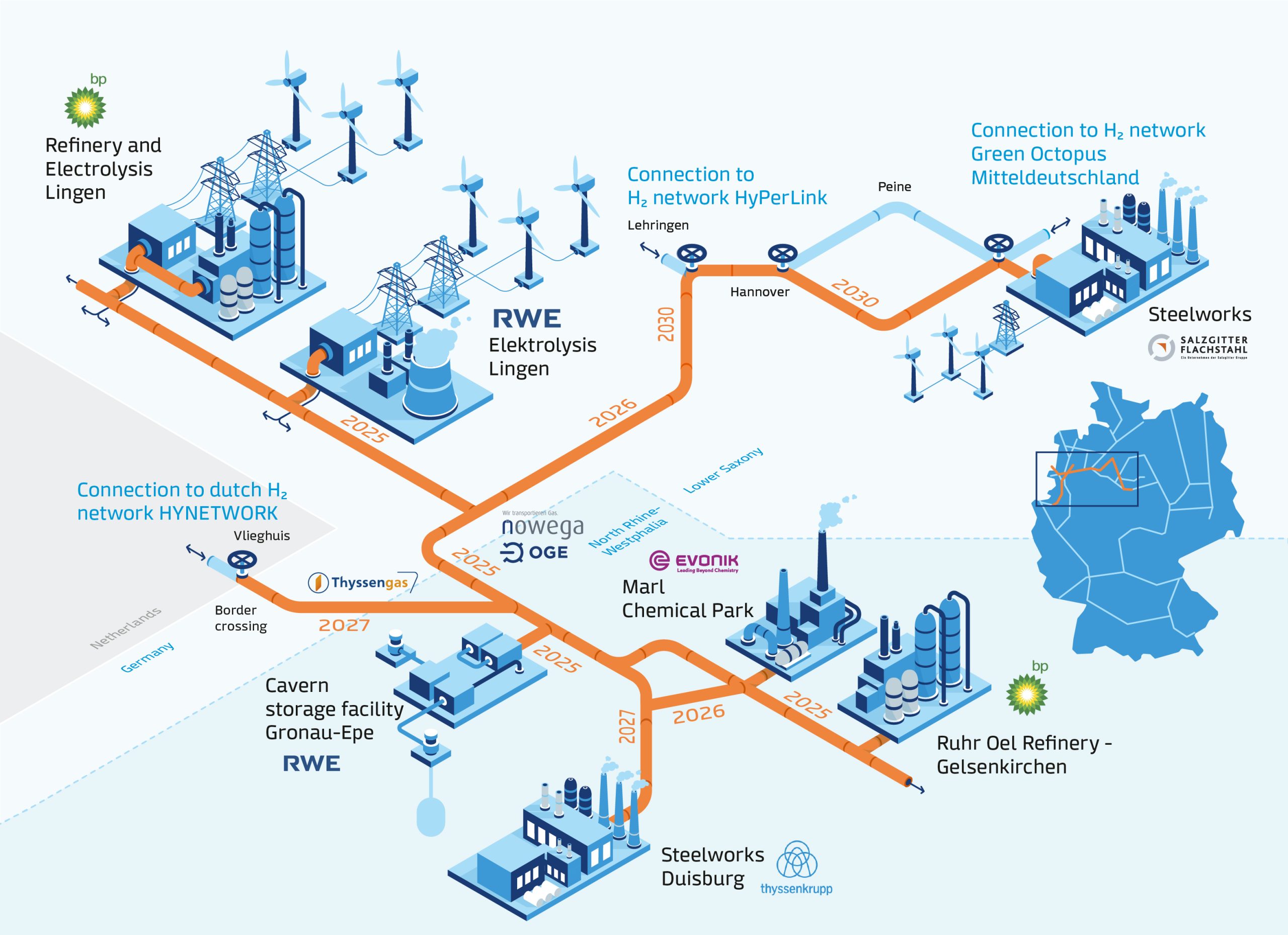

2030: Connecting the pieces

The final step is to connect Salzgitter AG via existing Nowega gas pipelines by 2030, which will be converted to transport hydrogen. By using the green hydrogen in refineries, in steel production and for other industrial uses, the overall project has a CO2 avoidance potential of up to 16 million tonnes by 2030.

The expansion of the project by partners from the transport sector and for the distribution of green hydrogen in the area is also already in preparation. Other partners of the GET H2 initiative have also submitted expressions of interest for IPCEI funding for projects aimed at establishing a hydrogen infrastructure.